adidas [FUTURECRAFT]: STRUNG

Adidas [FUTURECRAFT] is an initiative that marries innovation through data driven design and the traditional craft of cobbling. On October 8th, 2020 adidas unveiled their latest innovation, FUTURECRAFT: STRUNG. A new manufacturing process utilizing data driven design to create and manufacture high performance footwear for indivduals.

This project is a collaboration with KRAM/WEISSHAAR and the adidas FUTURE team

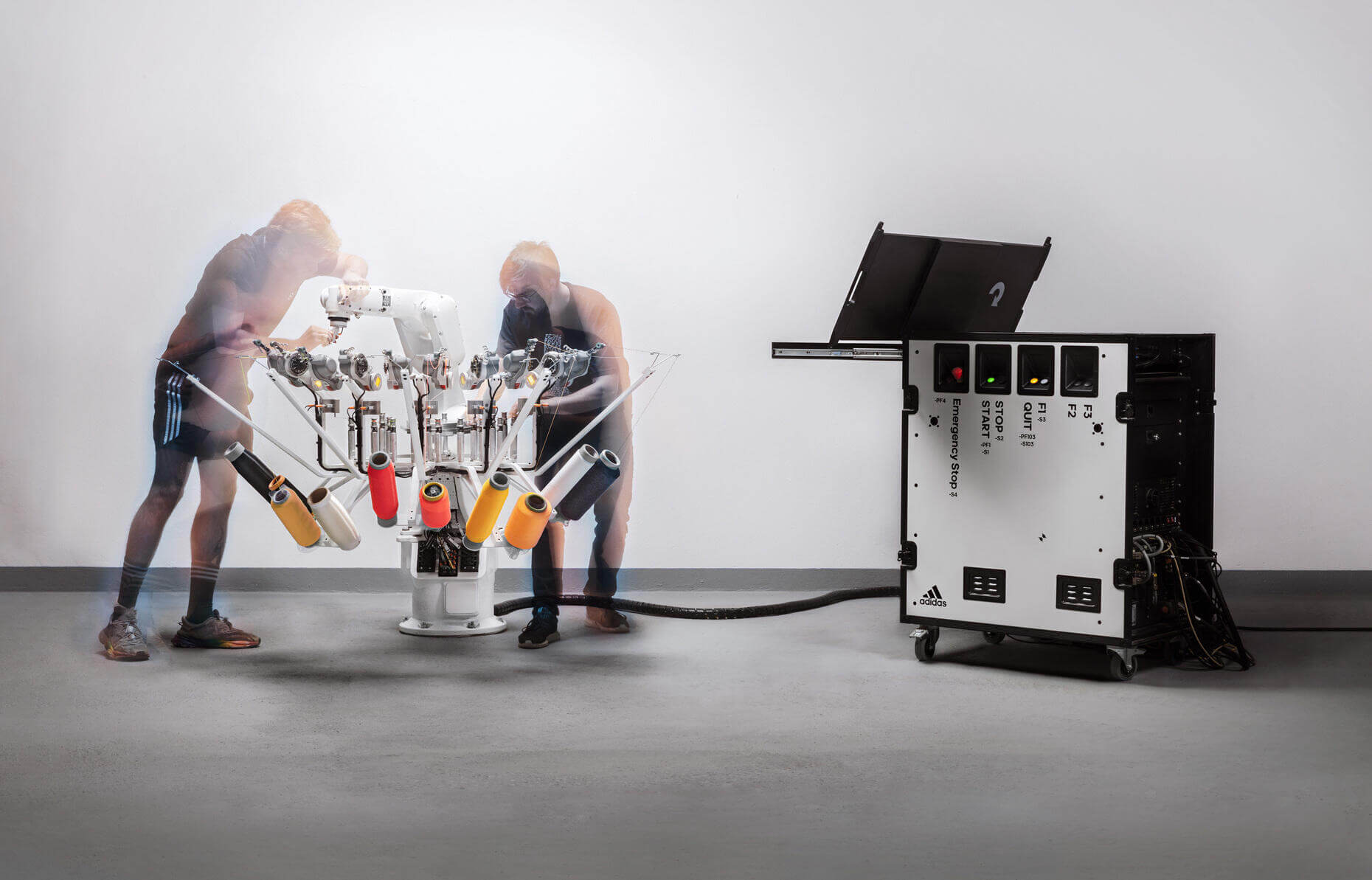

During my time as an intern I supported this project through 3D CAD work, construction of the machine (and its early interations), testing, prototyping, and designing footwear prototypes.

FUTURECRAFT_STRUNG

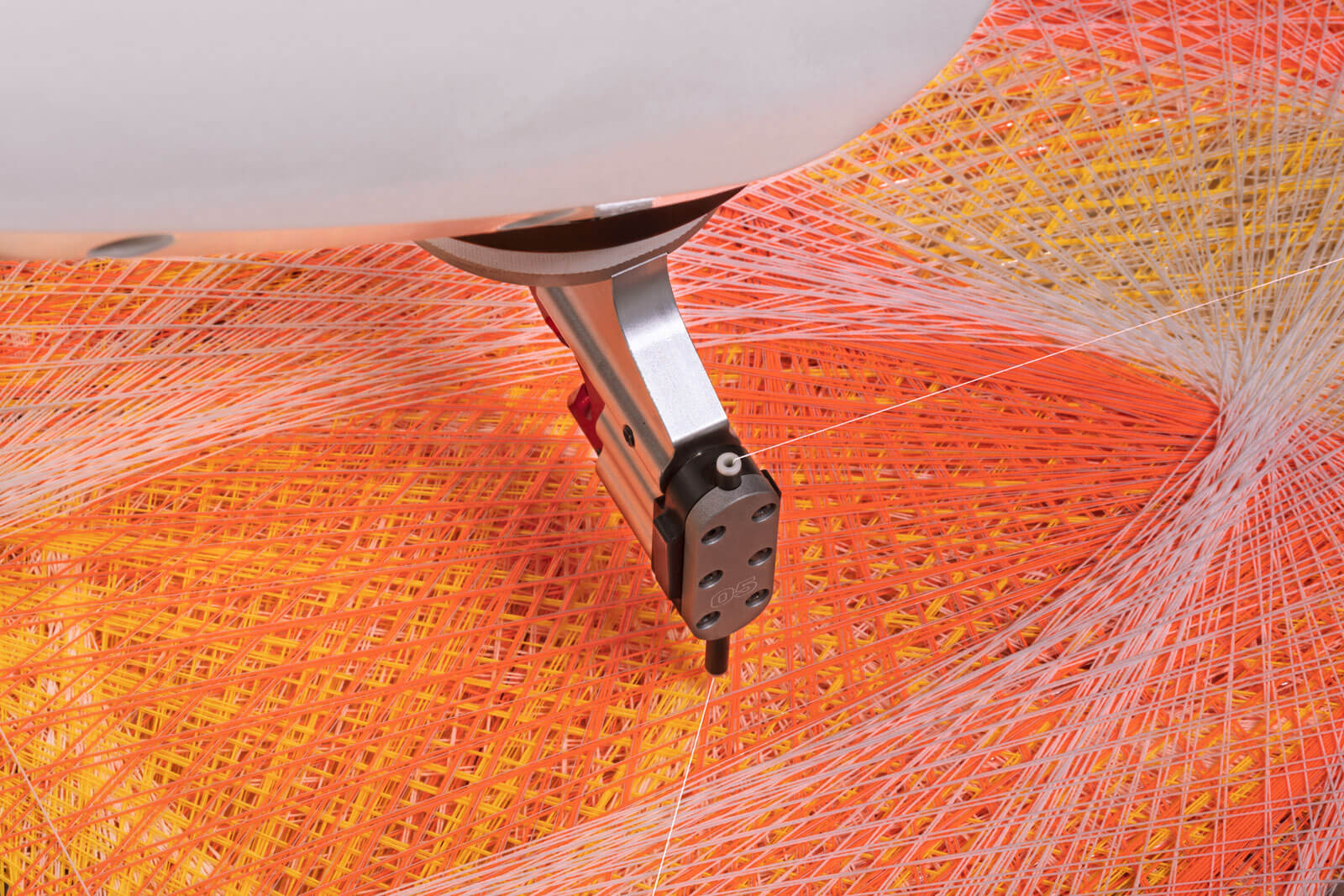

STRUNG is an entirely new way of creating a textile that is specifically aimed at making high performance footwear uppers. The process can not be classified as neither knitting nor weaving allowing for multi directional specificity without the constraints of the weft and loft logic of conventional textiles.

The fully integrated design and manufacturing environment allows us to create a lightweight upper where each thread is strategically placed for a seamless, lightweight fit. The STRUNG process codes in functionality at the exact spot where the athlete needs it within a single piece of material, free from inhibiting excess component or seams.

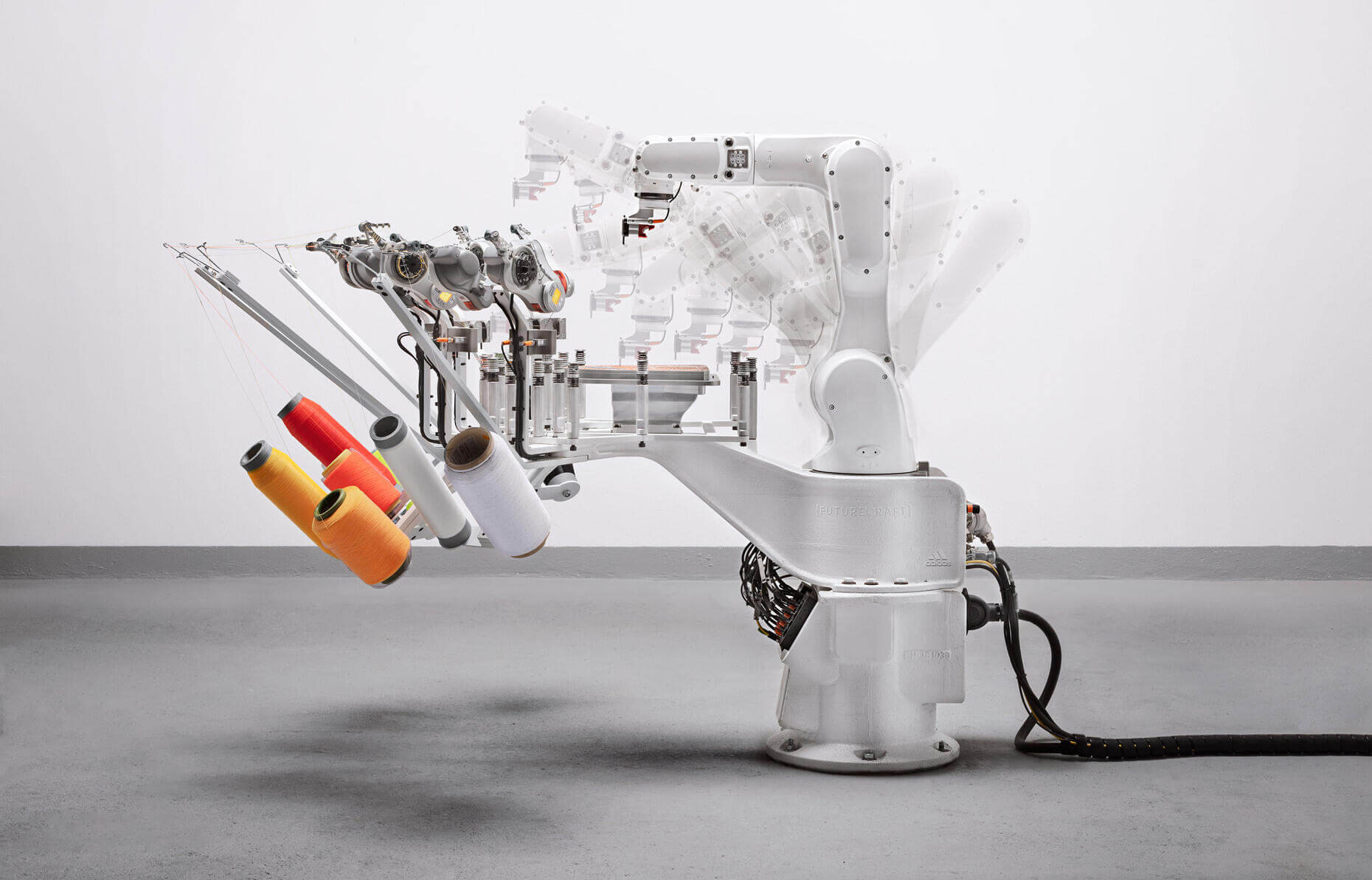

Working with and for adidas FUTURE, the secretive multidisciplinary R&D arm of adidas, KRAM/WEISSHAAR have designed, engineered and built the software and hardware tools that enable the design, engineering, prototyping and production of STRUNG uppers.

PLAYING_WITH_STRING THEORY

The software behind STRUNG delivers the deep knowledge of the brand at the designer's fingertips. The STRUNG interface incorporates athlete data and sport science insights drawn from the adidas Athlete Intelligence Engine as well as advanced simulation tools and projects them into a virtual work space. The knowledge of the many experts involved in the development of the materials, patterns and components is translated into actionable code that facilitates immediate product creation and manfacturing. The resulting physical sample is placed onto the designers' desk within minutes.

STRUNG_ROBOTIC CELL

This project reimagines multi disciplinary collaboration in the 21st century. Built as a lightweight and ultra compact micro factory the FUTURECRAFT.STRUNG robotic cell features a series of proprietary hardware and software inventions that facilitate close human-robot interaction. Three units working across different continents enable non-stop development - and provided an edge in times of COVID-19 related travel restrictions.

SHOES_STRUNG UP

The FUTURECRAFT.STRUNG shoe is the pacecar for this technology. With the ADIDAS 4D tooling and STRUNG upper it combines the brand's latest and most powerful high-resolution creation technologies to produce the industry’s first entirely data-driven footwear for a specific runner profile:

short-distance training runs at 5m/s or faster.

The upper has a lightweight cocooned feel and fit, locking the heel to prevent slip, with stiffer and stronger red threads placed at the midfoot, toe-box, and heel, and suppler yellow threads in the forefoot for flexibility. These threads blend each of those features together within the material to provide precise fit and support through the gait cycle.

The all new midsole features a new shape to cater for forefoot strikers. The heel has been minimized to remove weight and the rubber outsole is specifically engineered to provide traction just where needed.